A dozen common Kjeldahl nitrogen analyzer problems

1. In which industries are nitrogen analyzers mainly used?

Answer: Nitrogen analyzers are mainly automated instruments that can independently determine nitrogen content based on the classic Kjeldahl method. They are widely used in the analysis and determination of crude protein in grain, food, feed, soil, fertilizer, water, sediment, chemicals, dairy products, brewing, sugar making, medicine, coal, rubber and other materials.

2. What are the common faults and solutions for nitrogen analyzers during use?

Answer: 1. The alkali pump and pipeline are blocked. The instrument should be cleaned and maintained frequently after use.

2. The service life of the steam generator is short. Distilled water or pure water must be used in the steam generator to avoid the formation of scale.

3. What is the difference between the automatic nitrogen analyzer and the traditional manual method?

Answer: After setting up the corresponding laboratory conditions, the automatic nitrogen analyzer does not require human intervention during the entire experimental process. It has many advantages such as fast testing speed, high efficiency, good parallelism of sample test results, and low risk factor.

4. How to ensure the recovery rate of the sample?

A: The main factors affecting the recovery rate are distillation time, whether the addition of alkali and boric acid is excessive, whether the digestion is complete, and the sealing of the instrument. The cooling water flow, water pressure, and water temperature are too high.

5. What does the sample recovery rate represent?

A: The sample recovery rate represents the accuracy of the instrument and also reflects the manufacturing process of the entire instrument. Therefore, the sample recovery rate is an important indicator for evaluating the quality of the equipment.

6. How to verify the accuracy of the test results of the nitrogen analyzer?

A: It can be verified with a standard sample with a known sample content. Generally, the configured ammonium sulfate is used for calibration of the instrument.

7. Can the nitrogen analyzer use other color indicators?

A: If manual titration is used, other color indicators can be selected. If a fully automatic instrument is used, the color indicator should be configured according to the ratio specified by the product, and other reagents cannot be replaced. The built-in color change process of the product has been adjusted to the best state when it leaves the factory, ensuring the accuracy of the results.

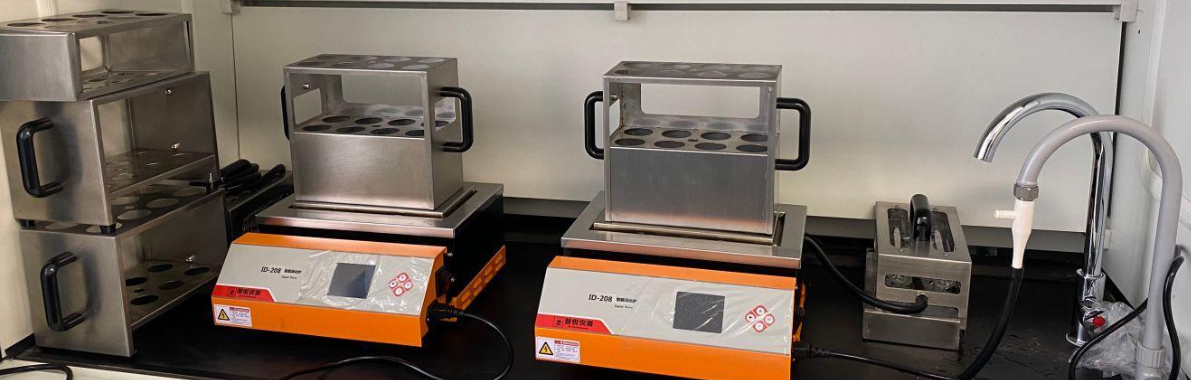

8. Can the nitrogen analyzer be equipped with digestion tubes of different specifications and different manufacturers?

A: No, each manufacturer's digestion tube has standard size and specifications. Different sizes are different from the matching machines. It is recommended to configure the digestion tube produced by the original factory.

9. In addition to determining the nitrogen content in the sample, can the nitrogen analyzer do other distillation experiments?

Answer: In theory, it can be done. It depends on different experiments and different needs of the experiments.

10. How to verify the accuracy of the test results of the nitrogen analyzer?

Answer: You can use standard samples with known sample content for verification. Generally, the configured ammonium sulfate is used for instrument calibration.

11. What special requirements does the nitrogen analyzer have for the laboratory environment?

Answer: 1. Normal laboratory power supply must be guaranteed.

2. The laboratory water supply and drainage must be smooth.

3. The instrument should be placed no more than 1.5m away from the tap water source.

4. According to national mandatory regulations, all digestion experiments must be carried out in a ventilated place.

12. Does the Kjeldahl nitrogen determination experiment need to be equipped with other instruments?

Answer: Yes, mainly balances, drying ovens, mortars, and basic experimental glass instruments with related reagents.

13. How long is the service life of the nitrogen analyzer?

A: The design service life of the nitrogen analyzer is 10 years, which depends on the amount of your own experiments and daily maintenance.

14. Sometimes bubbles will appear when the boric acid absorption liquid is absorbing. Will it affect the results?

A: No, because during the condensation process, air will enter the absorption liquid along with ammonia water and produce bubbles. This is a normal phenomenon and has no effect on the experimental results.

15. What are the vulnerable parts and consumables of the nitrogen analyzer?

A: The vulnerable parts of the nitrogen analyzer are mainly digestion tubes. Because they are glass products, collisions and scratches are inevitable during daily use. It is recommended to configure more digestion tubes. The consumables of the product are mainly reflected in the reagents used in daily experiments, mainly copper sulfate (catalyst), potassium sulfate (to increase the boiling point of sulfuric acid), concentrated sulfuric acid, boric acid, sodium hydroxide, hydrochloric acid, etc.

16. Can the nitrogen analyzer be used with digestion instruments of different brands?

A: To match digestion instruments of other brands, it is necessary to determine whether the digestion aperture of the digestion instrument is consistent with that of the supporting manufacturer. In order to ensure the accuracy and efficiency of the entire experimental results, it is recommended to purchase the digestion instrument that is originally provided by the manufacturer.

17. How to ensure the service life of the Kjeldahl nitrogen analyzer?

Answer: The service life of the nitrogen analyzer depends on the raw materials, processing technology and after-sales service used by different manufacturers. Because the Kjeldahl nitrogen determination experiment involves many factors such as strong acid, strong alkali, and high temperature, the daily care and maintenance of the instrument are also important factors in determining the service life of the instrument.

18. Does the nitrogen analyzer need to be identified by the quality inspection department?

Answer: The nitrogen analyzer is not included in the product catalog of the national mandatory inspection and is not a measuring instrument, so it does not require inspection by the quality inspection department.

More News