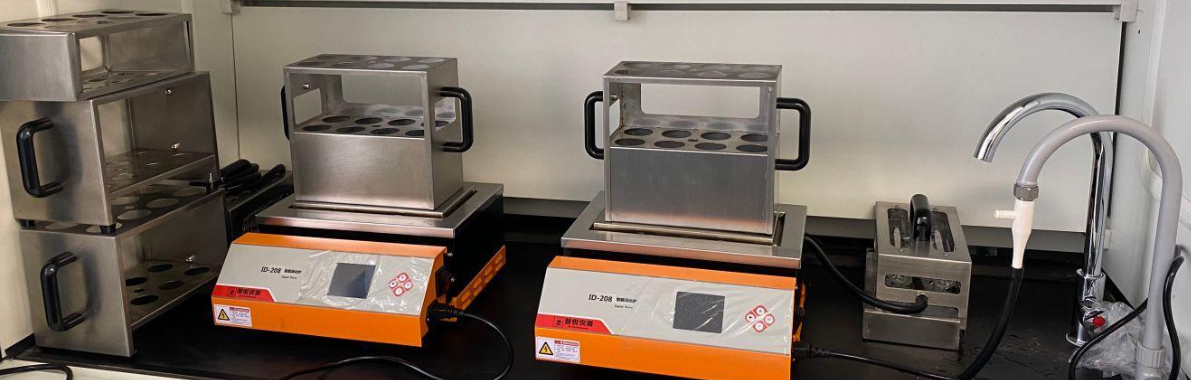

Precautions for Using the Fat Determination Apparatus (Soxhlet Extractor)

The automatic fat determination apparatus (Soxhlet extractor) is based on the Soxhlet extraction principle, integrating heating, soaking, extraction, washing, solvent recovery, and drying functions, to extract and separate fats and other organic substances. So, what should be noted when using the fat determination apparatus?

1. Sample Preparation Stage

(1) The sample should be uniformly crushed and dried in an oven. After weighing a specific amount of the sample, directly place it in the folded filter paper. A layer of defatted cotton should be added on top of the sample and pressed down to prevent the sample from floating during the experiment.

(2)

A. For low-fat samples such as grains and animal feed, approximately 2 grams of powdered sample should be accurately weighed to 0.0002 grams. First, insert a layer of defatted cotton at the bottom of the filter paper tube, then transfer the sample into the tube and cover the sample with a layer of defatted cotton.

B. For high-fat samples such as oilseeds, approximately 2 grams of the sample should be weighed and placed in a drying box. Dry it at 105°C for 30 minutes. While still hot, transfer the sample to a mortar and grind it. After grinding, add about 2 grams of defatted fine sand and grind together with the sample. The sample should reach a state where oil is released (but it should not be too sticky and should remain somewhat loose). Then, carefully transfer the sample into the filter paper tube, which has defatted cotton at the bottom. Use defatted cotton to dab a small amount of solvent, clean the mortar and any remaining sample and fat, and transfer it into the filter paper tube. Finally, press the sample down with defatted cotton at the top.

(3) Clean the aluminum cup with hot water until no residue remains. Dry it in an oven at 105°C for about 1 hour. Afterward, remove it, label it, weigh it, and store it in a desiccator to cool for later use.

2. Testing Stage

(1) The solution added to the aluminum cup should cover the sample in the filter paper by about 2 cm to ensure that the solution fully penetrates the sample and facilitates the complete extraction of fat.

(2) During the soaking phase, the temperature should not be set too high, and the reflux speed should be around 120 drops per minute.

(3) Prior to soaking, it is best to pre-extract the sample for 20 minutes to moisten it with the solvent. This helps prevent the sample from floating, which could affect the results.

(4) The temperature of the condenser water should not exceed 24°C.

3. After the Experiment

(1) Clean the aluminum cup promptly and dry it. Store it in a dust-free space for later use.

(2) If the experiment is conducted during the winter and the laboratory temperature is below freezing, make sure to drain any water from the condenser to prevent the glass tube from freezing and breaking.

More News