How to Choose the Right Digestion Furnace

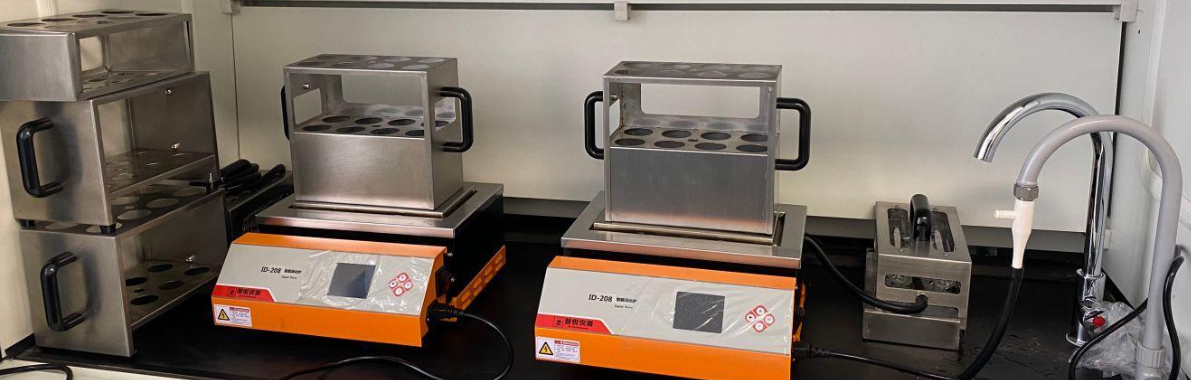

A digestion furnace is an essential tool for determining the protein content in samples. Therefore, choosing the right digestion furnace is extremely important for both businesses and users. Selecting a good product can greatly enhance the efficiency and accuracy of laboratory testing.

To begin with, when choosing a digestion furnace, it is crucial to understand the working environment and the key parameters of the furnace. Some points to pay attention to include:

Effective Temperature Control: The furnace must effectively control temperature fluctuations during the digestion process to prevent the sample from sticking to the walls due to rapid temperature increases.

Uniform Heating Across Multiple Holes: As digestion furnaces often process multiple samples at once, it is important that each hole reaches the same temperature by the end of the digestion process.

Even Heat Distribution: The furnace should ensure that each hole is evenly heated and that the furnace retains heat properly.

Corrosive Gases and Liquids: The digestion process can generate corrosive gases and liquids, so the furnace should be designed to protect critical components, such as the outer casing and digestion program board, from corrosion.

From the above, we can outline some clear directions for selecting a suitable digestion furnace:

Temperature Control Program: The furnace should have a program that allows for gradual temperature increases and stage-wise constant temperature holding to prevent sample wall sticking.

Uniform Heating Element: The furnace’s heating body should be well-constructed, with materials like aluminum alloy heating elements being commonly used for even digestion and consistent temperature across all holes.

Effective Insulation: Once the furnace reaches the desired temperature, good insulation is required to prevent rapid heat loss. High-quality heat-resistant and flame-retardant insulation materials are ideal for this purpose.

Corrosion Protection: Since the digestion process uses concentrated sulfuric acid, which can generate corrosive gases and liquids, the furnace casing should be coated with special anti-corrosion paint. Additionally, the digestion control board, which operates in a high-temperature environment, requires thermal insulation to avoid heat damage.

In conclusion, choosing the right digestion furnace is not difficult. By considering the above points, you can have a clear direction. Of course, factors such as price, quality, after-sales service, and brand should also be taken into account during the purchasing process. This ultimately depends on personal judgment.

More News