Routine Steps and Methods for Detecting Crude Protein in Animal Feed

1. Principle:

Under the action of a catalyst, concentrated sulfuric acid is used to decompose the organic matter in the sample, converting nitrogen-containing compounds into ammonium sulfate. Ammonia is then distilled by adding alkali, absorbed in boric acid solution, and subsequently titrated with standard hydrochloric acid solution. The nitrogen content is calculated, and the crude protein content is determined by multiplying the nitrogen content by the conversion factor of 6.25.

2. Operating Steps:

1) Weighing the Sample:

| Crude Protein Content (%) | Sample Weight (g) |

|---|---|

| < 10% (corn, rice, etc.) | 0.7 – 1.0 |

| 10 – 25% (wheat, etc.) | 0.5 – 0.7 |

| 25 – 35% (DDGS, citric acid lees, etc.) | 0.4 – 0.5 |

| 35 – 50% (soybean meal, peanut meal, rapeseed meal, etc.) | 0.25 – 0.4 |

| > 50% (fishmeal, feather meal, corn gluten meal, etc.) | 0.2 – 0.25 |

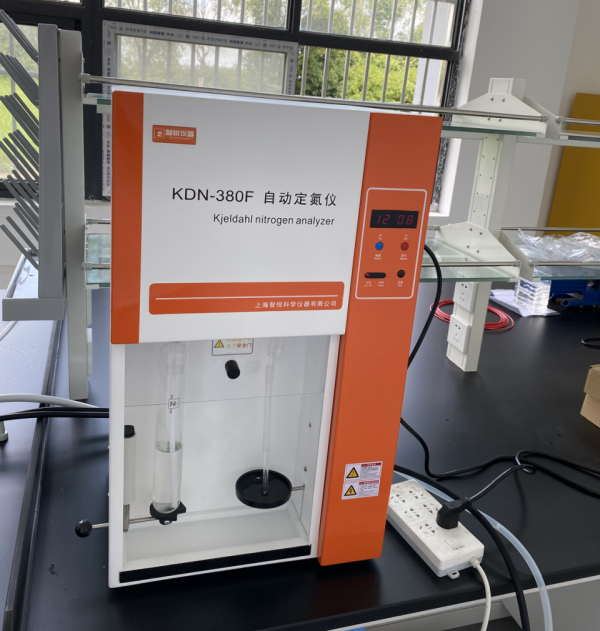

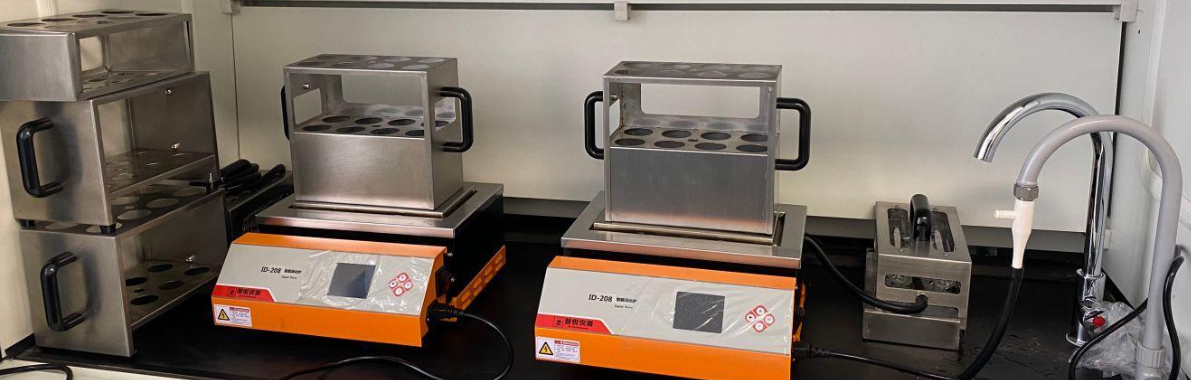

2) Sample Digestion:

Add 6.4g of catalyst (1:15 copper sulfate: potassium sulfate), and 12 mL of concentrated sulfuric acid into the digestion tube. Heat gradually to 420°C over approximately 2 hours. After cooling, add 20 mL of distilled water.

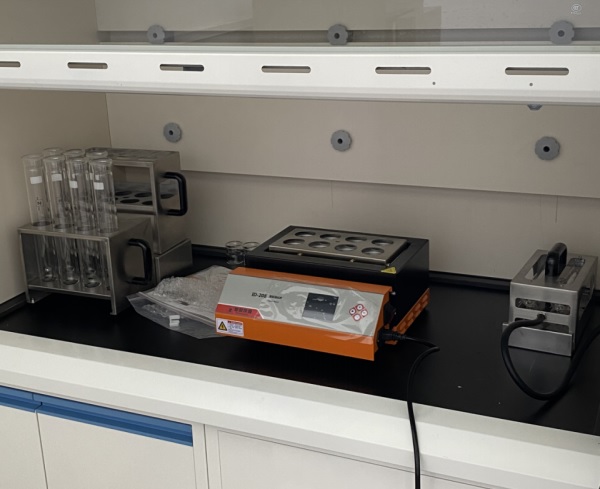

3) Ammonia Distillation:

Place the digestion tube with the digestion liquid into the distillation apparatus, using 30 mL of boric acid solution as the absorbent. Add 3 drops of mixed indicator solution. The cooling tube should be immersed in the receiving flask containing the absorbent solution. Add excess sodium hydroxide solution to the digestion tube for distillation. Distill for about 6–8 minutes, until about 200 mL of receiving liquid is collected, and the absorbent solution becomes neutral (pH paper test). Stop the distillation.

4) Titration:

Titrate the absorbing solution using a 0.1 mol/L hydrochloric acid standard solution. The endpoint is reached when the solution changes from blue-green to gray-red. At the same time, perform a blank test.

3. Key Control Points:

1) Reagents and Solutions:

Reagents should be nitrogen-free. All key reagents should be verified upon receipt.

Add the indicator solution immediately before use to ensure consistent quantity and color.

Reminder: Sulfuric acid and hydrochloric acid are Class III precursor chemicals, so they should be purchased, used, and stored legally.

2) Distillation Process:

Follow the operating instructions for the equipment strictly.

Check the status of the equipment carefully and troubleshoot any abnormalities.

Ensure the distillation tube is properly sealed.

Ensure the receiving flask is submerged below the liquid level.

Amount of alkali: If the solution turns black, the alkali or copper may be insufficient.

Time and volume are not the only factors to determine if distillation is complete. Pay attention to the pH of the distillation liquid (use universal pH paper, pH between 6–7).

3) Verification of the Distillation Step:

Method: Accurately weigh 0.2g of ammonium sulfate (accurate to 0.0002g) as a substitute for the sample. No digestion is required. Perform quantitative distillation using either the constant or semi-micro distillation method, but do not multiply by 6.25 to calculate.

Result: The nitrogen content of ammonium sulfate is found to be 21.19±0.2%.

Purpose: To check the airtightness of the instrument, alkali addition, distillation, and titration steps.

Timing: Conduct checks if abnormal data, instrument faults, or cleaning of the apparatus occurs, or as part of routine maintenance.

Note: Even if the nitrogen content in ammonium sulfate meets the requirements, this does not guarantee the accuracy of crude protein detection.

4) Titration Process:

The absorbing solution should be titrated immediately after collection.

Standard hydrochloric acid solution should be stored in tightly sealed containers, as hydrochloric acid is volatile. Use within two months.

Choose the correct burette size: either 25 mL or 50 mL.

Standardize the titration operation: Ensure consistent speed, technique, and reading.

Determine the endpoint using a white background.

5) Blank Determination:

Method: Only the catalyst is weighed and combined with concentrated sulfuric acid. Perform digestion, distillation, and titration as a blank test.

Purpose: To eliminate reagent blanks.

Requirements: The volume of 0.1 mol/L hydrochloric acid consumed during titration should not exceed 0.2 mL. The volume of 0.02 mol/L hydrochloric acid consumed should not exceed 0.3 mL.

More News