Precautions for Using the Intelligent Digestion Furnace

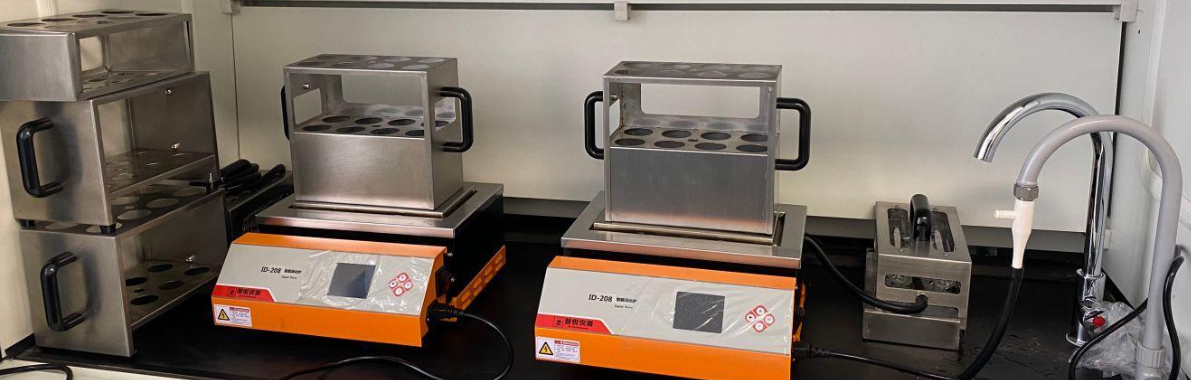

The intelligent digestion furnace is a sample digestion device developed based on the classic wet digestion principle. It offers advantages such as fast digestion, safety, and stability. It is widely used for the digestion of samples before chemical analysis in various fields, including feed, food, grains, soil, meat, and dairy products. It is an ideal companion for Kjeldahl nitrogen analyzers and other distillation equipment.

However, there are several precautions to follow during the use of the intelligent digestion furnace:

Before starting digestion, make sure to turn on the exhaust pump connected to the water faucet. It is important not to set the water pressure to the maximum; just ensure it is sufficient to properly exhaust the waste gases.

Set the temperature parameters for a staged temperature increase, gradually transitioning from a low flame to a high flame, in accordance with national standards. This prevents high temperatures from causing samples to stick to the walls of the furnace.

Aluminum ingots provide better heat distribution. Avoid dripping corrosive liquids such as sulfuric acid into the furnace holes, as this can damage the bottom of the furnace core.

If the number of samples for digestion is less than the number of furnace holes, place the samples in the middle hole of the aluminum ingot for better heat retention.

Handle the digestion racks and fume hoods with care when placing them.

After use, clean the digestion furnace promptly to prevent corrosive gases from damaging the furnace body.

More News