Reasons for Inaccurate Results in Kjeldahl Nitrogen Analyzer Testing

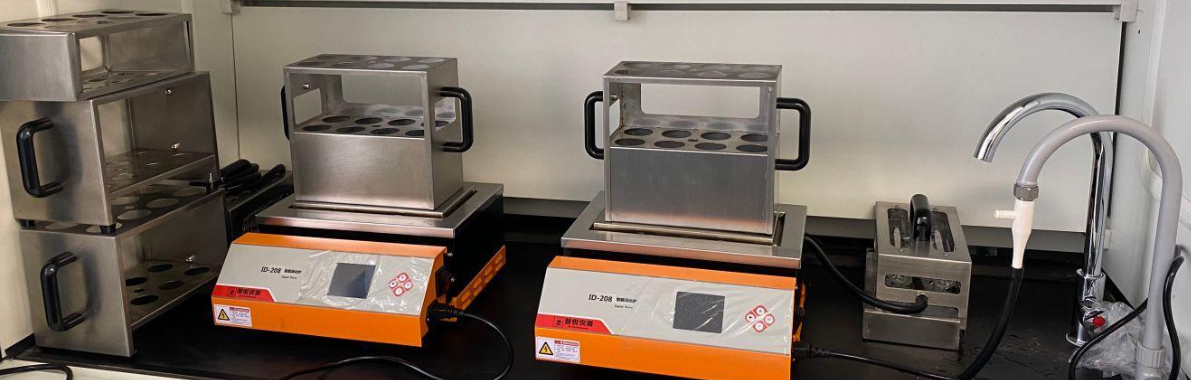

The Kjeldahl nitrogen analyzer is a specialized instrument based on the classical Kjeldahl method for determining the nitrogen content in samples. It has been widely used in fields such as food processing, grains, feed, water, soil, pharmaceuticals, tobacco, livestock, soil and fertilizer, environmental testing, medicine, pesticides, research, education, quality supervision, and more. From the perspective of testing principles, determining nitrogen content using the Kjeldahl nitrogen analyzer involves three main steps: sample digestion, distillation, and titration to calculate the nitrogen content. Therefore, the inaccuracy of results from the Kjeldahl nitrogen analyzer is mainly related to these three steps. Upon analysis, the key reasons affecting the accuracy of results can be summarized as follows:

1. Digestion Issues:

During digestion, if the temperature is too low or the time is insufficient, the sample may not be fully digested, and wall adherence may occur.

The sample, concentrated sulfuric acid, or catalyst is not added in the correct proportions before digestion, leading to incomplete digestion.

2. Titration Issues:

The hydrochloric acid or sulfuric acid standard solution is too concentrated. (Manual titration may result in lower recovery rates).

The hydrochloric acid or sulfuric acid standard solution has been stored for too long, causing the concentration to become inaccurate. (It is recommended not to store for more than one month; if storage time exceeds this, the solution should be re-prepared.)

3. Distillation Issues:

The internal pipes, condenser, or anti-splash pipes of the Kjeldahl nitrogen analyzer’s distillation system are damaged, causing ammonia gas leakage.

The collection liquid is too little and does not cover the outlet of the collection tube.

If the temperature of the collection liquid exceeds a certain level, ammonia gas is likely to escape. This happens when the condenser temperature is too high or the collection liquid is above the normal temperature.

Of course, the above points refer to the most common causes of inaccurate results in Kjeldahl nitrogen analyzer testing, but there are other less common factors, such as issues with the balance (leading to inaccurate sample weighing), uneven sample grinding, use of expired or degraded reagents, or operator errors. In such cases, it is necessary to troubleshoot systematically to identify the root cause.

To ensure accurate test results, in addition to choosing a high-performance, cost-effective Kjeldahl nitrogen analyzer, it is important to conduct proper calibration and maintenance of the instrument before testing. During operation, strict adherence to the instrument’s operational procedures is essential, including proper temperature settings during digestion, correct catalyst ratios, digestion times, and other factors. Every detail can influence the results, so despite having professional equipment, the operational process must not be overlooked.

More News