Common Issues and Solutions for Kjeldahl Nitrogen Analyzer

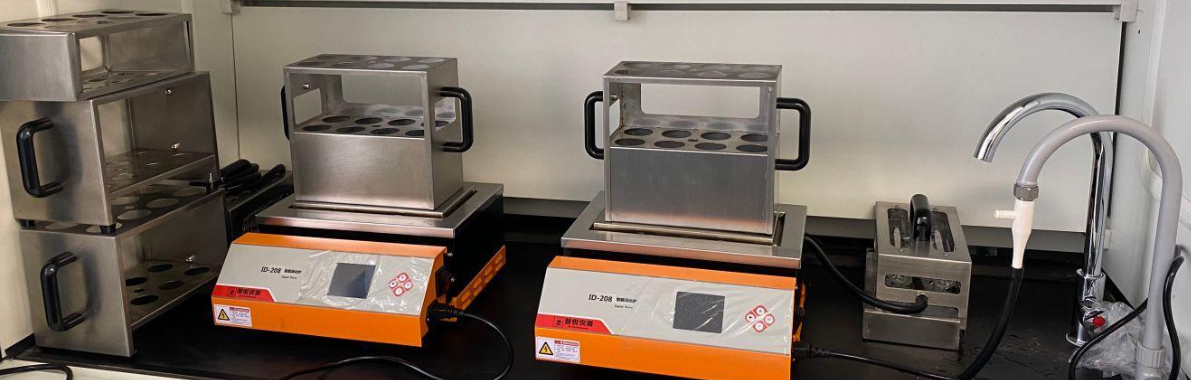

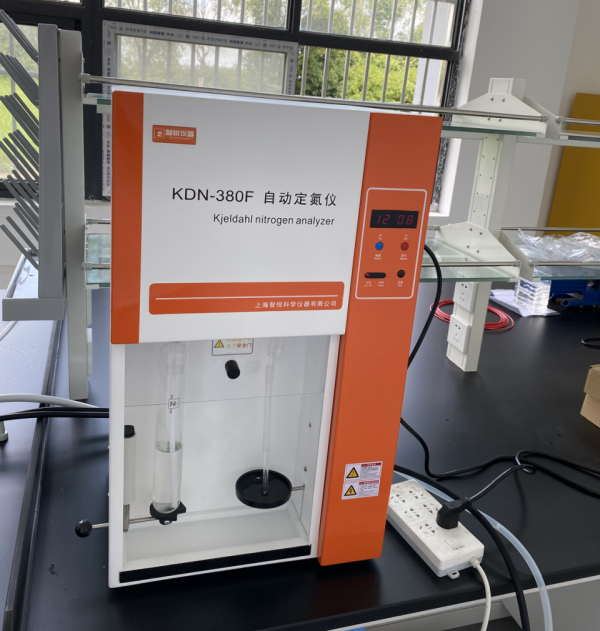

The Kjeldahl nitrogen analyzer, known for its ease of operation and cost-effectiveness, is widely used for the determination of nitrogen or protein content in samples such as food, crops, seeds, soil, fertilizers, and more. Most Kjeldahl nitrogen analyzers on the market are based on the Kjeldahl method to detect and analyze the nitrogen content in samples. The main components of the instrument include digestion, distillation, and titration units. The typical process is as follows: Under the action of a catalyst, sulfuric acid is used to digest the sample, breaking down organic nitrogen into inorganic nitrogen and forming ammonium sulfate. Afterward, alkaline distillation is carried out by adding an alkali solution to the sulfuric acid-digested ammonium sulfate under heat vapor. Finally, a standard acid solution is used for titration, and the nitrogen content is calculated using a formula. Kjeldahl nitrogen analyzers are commonly used in laboratories, but users may encounter various issues during operation.

What are the common types of Kjeldahl nitrogen analyzers on the market?

Currently, there are many types of Kjeldahl nitrogen analyzers on the market, with the most common classification being:

Semi-automatic Kjeldahl analyzer: Only the distillation process is automated, while titration requires manual intervention. Semi-automatic analyzers are further divided into two types:

Fully automatic Kjeldahl analyzer: An integrated system for distillation and titration, where after digestion, the instrument automatically adds water, adds alkali, replenishes water, adds acid, performs titration, and prints the results. The entire process is automated, reducing laboratory staff workload and improving efficiency while ensuring more accurate results.

Manual addition of alkali, manual addition of water, manual control of distillation time, etc.

Automatic addition of alkali, automatic water replenishment, automatic acid addition, with no manual intervention required throughout the distillation process.

What industries primarily use Kjeldahl nitrogen analyzers?

Kjeldahl nitrogen analyzers are mainly used to measure the nitrogen and crude protein content in samples. They are widely used in industries such as grain, food, animal feed, soil, fertilizer, water, sediment, chemicals, dairy products, brewing, sugar production, pharmaceuticals, coal, rubber, and others for crude protein analysis.

What are the water quality requirements for a Kjeldahl nitrogen analyzer?

The steam generator of the Kjeldahl nitrogen analyzer requires distilled water, while the condenser tube can use tap water. If the instrument is not used for a long time, the water in the steam generator should be drained to prevent it from deteriorating.

What to do if water cannot be added to the steam generator when the Kjeldahl nitrogen analyzer is powered on?

If the pump makes a sound but water cannot be added (and the water tank has water), the possible causes are:

a. Open the drain valve to release any blockages: The glass bottle may contain air, which creates a vacuum and prevents water from entering.

b. If there is a sound from the pump, it may be clogged. You need to dismantle and clean it or replace the pump.

c. If there is no sound from the pump, there may be an issue with the pump or the control board, and you need to troubleshoot.

d. If the pump diaphragm is dry, lift the pipe and add some water, then power on the system to moisten it.

Is it normal for the Kjeldahl nitrogen analyzer to make loud noises during operation?

This is a normal phenomenon. The noise comes from the normal operation of the internal water pump and gas valve of the instrument.

Will the appearance of bubbles in the boric acid absorption solution during absorption affect the results?

No, this will not affect the results. During the condensation process, air may accompany the ammonia water into the boric acid absorption solution, causing bubbles. This is normal and does not affect the experimental results.

Is it normal for the Kjeldahl nitrogen analyzer to make a sound every 3-5 seconds during operation?

Yes, this sound is normal. During the operation of the instrument, the steam generator continuously heats and generates steam, which consumes water, causing the water level sensor to detect low water levels. The instrument will automatically activate the water pump to replenish water, and the sound is the water pump operating, which is a normal occurrence.

More News